Reserves & Resources

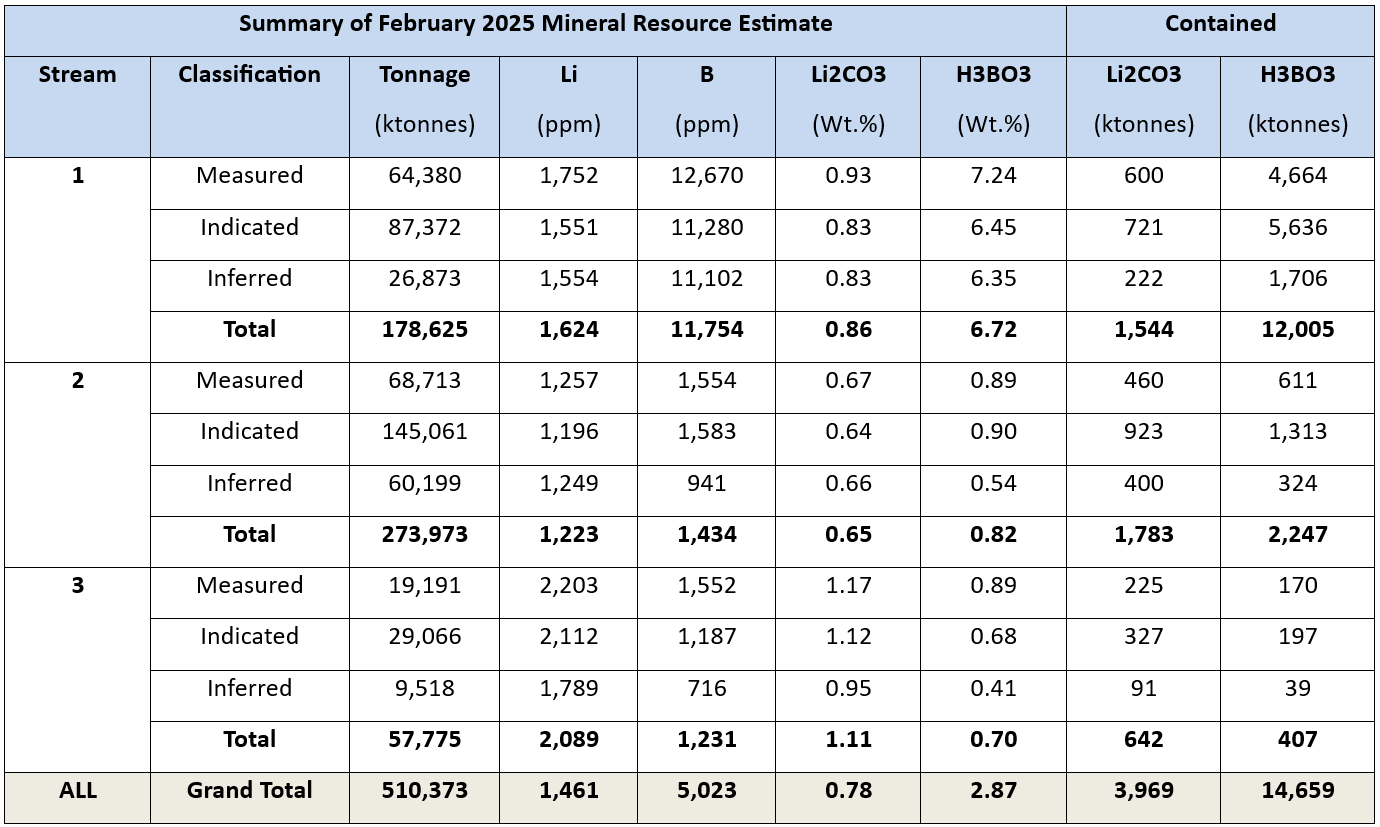

A summary of the February 2025 Mineral Resource estimate is provided in the table below. Note that Mineral Resources are reported inclusive of the Ore Reserve.

February 2025 Mineral Resource Estimate for Rhyolite Ridge South Basin

notes

- ktonnes- thousand tonnes (metric); Li= lithium; B= boron; ppm= parts per million; Li2CO3 = lithium carbonate; H3BO3 = boric acid.

- Totals may differ due to rounding, Mineral Resources reported on a dry in-situ basis. Lithium is converted to Equivalent Contained Tonnes of Lithium Carbonate (Li2CO3) using a stochiometric conversion factor of 5.322, and boron is converted to Equivalent Contained Tonnes of Boric Acid (H3BO3) using a stochiometric conversion factor of 5.718. Equivalent stochiometric conversion factors are derived from the molecular weights of the individual elements which make up Lithium Carbonate (Li2CO3) and Boric Acid (H3BO3).

- The statement of estimates of Mineral Resources has been compiled by Mr. Herbert E. Welhener, a Competent Person is a Registered Member of the SME (Society for Mining, Metallurgy, and Exploration), and is a QP Member of MMSA (the Mining and Metallurgical Society of America). Mr. Welhener is a full-time employee of IMC Inc. and is independent of Ioneer and its affiliates. Mr. Welhener has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (JORC Code 2012).

- All Mineral Resource figures reported in the table above represent estimates at February 2025. Mineral Resource estimates are not precise calculations, being dependent on the interpretation of limited information on the location, shape and continuity of the occurrence and on the available sampling results. The totals contained in the above table have been rounded to reflect the relative uncertainty of the estimate.

- Mineral Resources are reported in accordance with the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The Joint Ore Reserves Committee Code – JORC 2012 Edition).

- The Mineral Resource estimate is the result of determining the mineralized material that has a reasonable prospect of economic extraction. In making this determination, constraints were applied to the geological model based upon a pit optimization analysis that defined a conceptual pit shell limit. The conceptual pit shell was based upon a net value per tonne calculation including a 5,000ppm boron cut-off grade for high boron – high lithium (HiB-Li) mineralization (Stream 1) and a $16.54/tonne net value cut-off grade for low boron (LoB-Li) mineralization below 5,000ppm boron broke into two material types, low clay and high clay material respectfully (Stream 2 and Stream 3). The pit shell was constrained by a conceptual Mineral Resource optimized pit shell for the purpose of establishing reasonable prospects of eventual economic extraction based on potential mining, metallurgical and processing grade parameters identified by mining, metallurgical and processing studies performed to date on the Project. Key inputs in developing the Mineral Resource pit shell included a 5,000ppm boron cut-off grade for HiB-Li mineralization, $16.54/tonne net value cut-off grade for LoB-Li low clay mineralization and LoB-Li high clay mineralization; mining cost of US$1.69 /tonne; G&A cost of US$16.54 /process tonne; plant feed processing and grade control costs which range between US$20.27/tonne and US$98.73/tonne of plant feed (based on the acid consumption per stream and the mineral resource average grades); boron and lithium recovery for Stream 1 of 80.2% and 85.7%; Stream 2 and 3: M5 65% and 78%, B5 80.2% and 85.7%, S5 50% and 88%, L6 37% and 85%, respectively; boric acid sales price of US$1,016.67/tonne; lithium carbonate sales price of US$17,868.50/tonne.

In December 2022, the United States Fish and Wildlife Service (USFWS) listed Tiehm’s buckwheat as an endangered species under the Endangered Species Act (ESA) and has designated critical habitat by way of applying a 500 m radius around several distinct plant populations that occur on the Project site. Ioneer is committed to the protection and conservation of the Tiehm’s buckwheat. The Project’s Mine Plan of Operations, approved by the BLM in October 2024, has no direct impact on Tiehm’s buckwheat and includes measures to minimise and mitigate for indirect impacts within the designated critical habitat areas identified.

The mineral resource pit shell used to constrain the February 2025 Mineral Resource estimate was not adjusted to account for any impacts from avoidance of Tiehm’s buckwheat or minimisation of disturbance within the designated critical habitat. Environmental and permitting assumptions and factors have not been taken into consideration during modifying factors studies for the Project. The tonnes and grade within the avoidance polygons have not been removed from the Mineral Resources for the February 2025 estimate. Environmental and permitting assumptions and factors may be taken into consideration during future modifying factors studies for the Project. These permitting assumptions and factors may result in potential changes to the Mineral Resource footprint in the future.

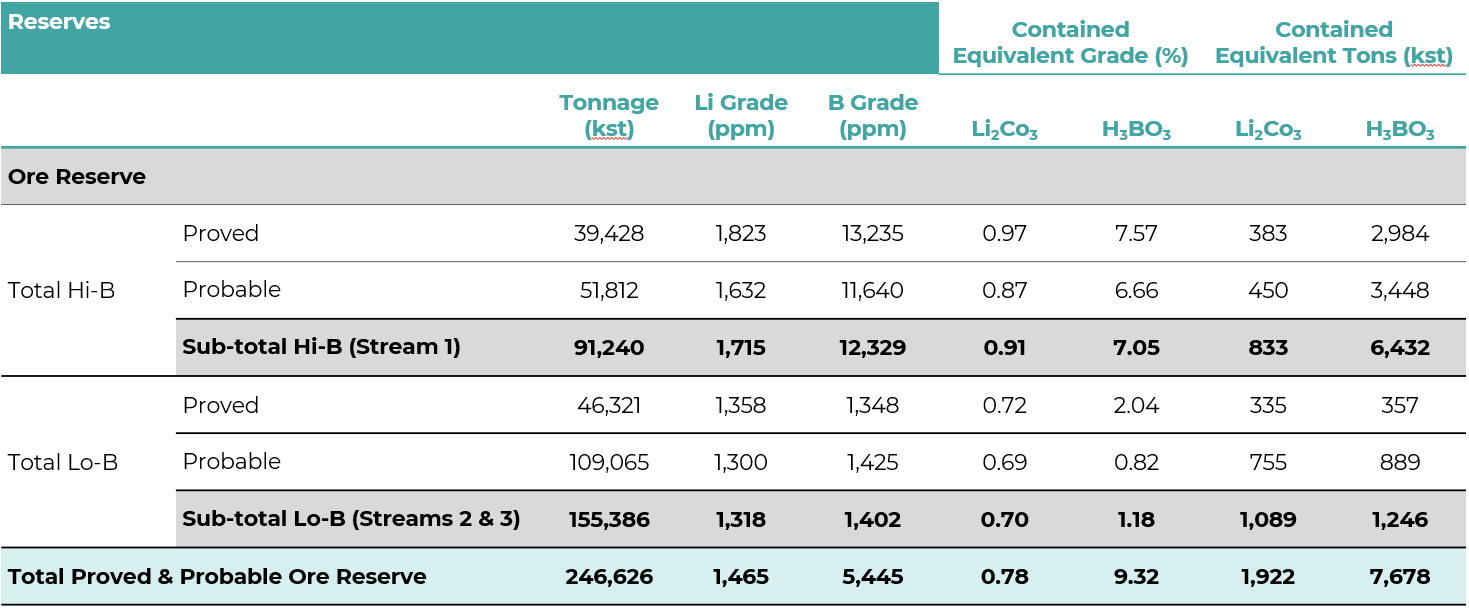

A summary of the 2025 Ore Reserve estimate is provided in the table below. The Ore Reserve is the economically mineable part of the Measured and Indicated Resource. It includes allowances for mining dilution and ore losses in mining. Appropriate assessments and studies have been carried out and include consideration of and modification by realistically assumed mining, metallurgical, economic, marketing, legal, environmental, social, and governmental factors. These assessments demonstrate at the time of reporting that the extraction could be reasonably justified. After the application of modifying factors, the Measured and Indicated resources within the engineered pit design have been converted to the following Proven and Probable Reserves.

2025 Ore Reserve Estimate for Rhyolite Ridge South Basin (Metric)

notes

- The statement of estimates of Ore Reserves has been compiled by Mr. Joseph S.C. McNaughton, a Competent Person is a Registered Professional Engineer in State of Arizona. Mr McNaughton is a full-time employee of IMC Inc. and is independent of Ioneer and its affiliates. Mr. Joseph McNaughton is responsible for the estimate, has sufficient experience that is relevant to the style of mineralization and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the JORC Code (2012).

- The ore reserve estimates the result of determining the measured and indicated resource that incorporates modifying factors demonstrating that it is economically minable, allowing for the conversion to proven and probable. In making this determination, constraints were applied to the geological model based upon a pit optimization analysis that defined a conceptual pit shell limit. The conceptual pit shell was based upon a net value per tonne calculation including a 5,000ppm boron cut-off grade for high boron – high lithium (HiB-Li) mineralization (Stream 1) and a $16.54/tonne net value cut-off grade for low boron (LoB-Li) mineralization below 5,000ppm boron broke into two material types, low clay and high clay material respectfully (Stream 2 and Stream 3). The pit shell was constrained by a conceptual Mineral Resource optimized pit shell for the purpose of establishing reasonable prospects of eventual economic extraction based on potential mining, metallurgical and processing grade parameters identified by mining, metallurgical and processing studies performed to date on the Project. The conceptual pit shell was used a guide to the engineered quarry designs used to constrain the Mineral Reserves.

- Key inputs in developing the Mineral Resource pit shell included a 5,000ppm boron cut-off grade for HiB-Li mineralization, $16.54/tonne net value cut-off grade for LoB-Li low clay mineralization and LoB-Li high clay mineralization; mining cost of US$1.69 /tonne; G&A cost of US$16.54 /process tonne; plant feed processing and grade control costs which range between US$20.27/tonne and US$98.73/tonne of plant feed (based on the acid consumption per stream and the mineral resource average grades); boron and lithium recovery for Stream 1 of 80.2% and 85.7%; Stream 2 and 3: M5 65% and 78%, B5 80.2% and 85.7%, S5 50% and 88%, L6 37% and 85%, respectively; boric acid sales price of US$1,172.78/tonne; lithium carbonate sales price of US$19,351.38/tonne were selected based on the market analysis.

- Ore reserves are based on a block model that is 7.62m x 7.62m30 in plan and 9.14m high. The model block size used for the ore reserve estimate is based on selected mining equipment and approached used within the mine plan. As a result, the dilution and ore loss are incorporated within the block model. On average, the reserve experienced a 308% increase in process tonnage, with lithium and boron grades decreasing by 18% and 65%, respectively. This resulted in a 428% and 167% increase in the tons of contained lithium carbonate and boric acid in the process streams when transitioning from mineral resource to ore reserve.

- Ore reserves reported on a dry in-situ basis. The contained and recovered lithium carbonate and boric acid are reported in the table above in metric tonnes. Lithium is converted to equivalent contained tonnes of lithium carbonate using a stochiometric conversion factor of 5.322, and boron is converted to equivalent contained tonnes of boric acid using a stochiometric conversion factor of 5.718. Equivalent stochiometric conversion factors are derived from the molecular weights of the individual elements which make up lithium carbonate and boric acid. The equivalent recovered tons of lithium carbonate and boric acid is the portion of the contained tonnage that can be recovered after processing.

- All ore reserve figures represent estimates as of May 2025. Ore reserve estimates are not precise calculations, being dependent on the interpretation of limited information on the location, shape and continuity of the occurrence and on the available sampling results. The totals have been rounded to reflect the relative uncertainty of the estimate. Totals may not sum due to rounding.

- Kt – thousand metric tonnes, MT – million metric tonnes, kst = thousand short tons; Li = lithium; B = boron; ppm= parts per million; Li2CO3 = lithium carbonate; H3BO3 = boric acid. Equivalent lithium carbonate and boric acid grades have been rounded to the nearest tenth of a percent.